- Sfoglia le categorie

- VALVOLA A FARFALLA RKS

- RKS GATE VALVE

- RKS CHECK VALVE

- Valvola di ago RKS

- Valvola di controllo RKS.

- Valvola di rilascio dell'aria RKS

- VALVOLA A SFERA RKS

- RACCORDO TUBO RKS

- RKS GLOBE VALVE

- ATTUATORE RKS

- Filtro RKS

- Lanciatore e ricevitore di suini

- Vasi a pressione in fibra di vetro RKS

- Prodotto principale

- Contattaci

-

RKSfluid Flow Control Company

Web:www.rksfluid.com

Tel: 86 24 2318 0188

Fax: 86 24 2318 0788

Posta: info@rksfluid.com Contatta ora

- sottoscrivi

-

Ricevi aggiornamenti via e-mail sui nuovi prodotti

China valve DN100 ductile iron multifunctional water pump control valve factory price

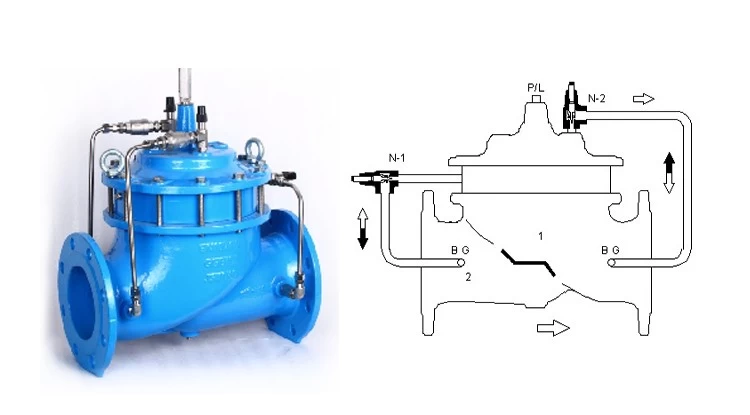

- Product Name:Automatic Hydraulic Control Valve

- Size:DN40-DN1200

- Working Medium:Water, Oil

- Temperature:0°C~70°C

- Body:DI/SS/Bronze

- O-ring:NBR/EPDM/VITON

- Seat: SS/Brass/Bronze

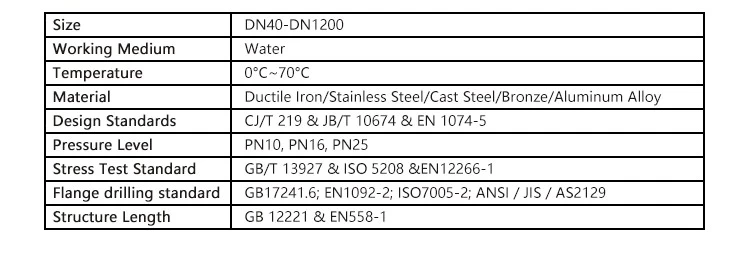

- Material:Ductile Iron/Stainless Steel/Cast Steel/Bronze/Aluminum Alloy

- Design Standards:CJ/T 219 & JB/T 10674 & EN 1074-5

- Pressure Level:PN10, PN16, PN25

- Stress Test Standard:GB/T 13927 & ISO 5208 &EN12266-1

- Flange drilling standard:GB17241.6; EN1092-2; ISO7005-2; ANSI / JIS / AS2129

- Structure Length:GB 12221 & EN558-1

- Face to Face:GB 12221 / EN 558-1 / ISO 5752 Series 1

Caratteristiche:

Fully bore globe pattern design, lowest head loss while fully open

Keep stable working condition even the flow rate close to zero

High sensitive and strength fabric reinforced diaphragm

- 1000000 cycles test between fully close and open with working pressure

- 5 times of working pressure destructive test

Most components are machined by CNC

Fusion bonded epoxy coating process is based on GSK & WIS standard

High standard production test

- Seal test: Low pressure 0.5 bar

High pressure 1.1xPN+1 bar

- Shell test: 1.5xPN+1 bar

- Pressure modulated vibration: +/-0.2 bar

Data collected automatically 1000 times/sec, display with static or dynamic chart

Easy installation, operation and free maintenance

Different materials with WRAS/KTW/NSF/FDA/ACS certification to meet different market

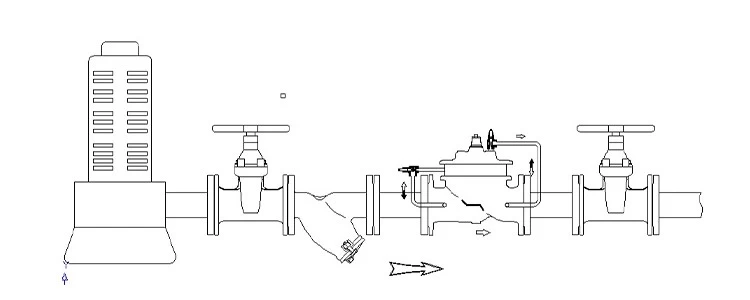

The 745X dual-chamber multi-function pump control valve is installed at the pump outlet to prevent and eliminate the damage of water hammer to the pipeline system/pump when the pump is turned on/off;

When the pump opened, the inlet pressure gradually into the valve cavity, so that the valve slowly open, open speed can be adjusted by the needle valve;

When the pump suddenly power failure or stop pumping, lift-off valve disc in its own gravity, Spring Force after the return of the back end of the water hammer force quickly closed.Prevent the back-end of the high-pressure water hammer on the front of the pump damage. Valve closing speed can be adjusted by needle valve or ball valve.

Ⅰ Business area: fluid control products, technology and environmental protection products.

Ⅱ Advanced CNC machining centers, professional process cells, wide-range welding equipment, automatic assembly lines and coating.

Ⅲ China's standard reference unit, to participate in the development of relevant valve industry standards.

Ⅳ We have set up a research and development center in Houston, Texas, in the United States.

Ⅴ Product Standard: GB, German Standard, American Standard, TUV CE, ISO 9001, ADWO-2000, TS, PED, WRC WRAS, KTW, API 6D, API609.

VI Main production: valvola a farfalla, valvola a sfera, valvola del cancello, valvola di ritegno, valvole globali, raccordi per tubi, attuatore manuale / pneumatico / elettrico, parti della valvola

Ⅱ Advanced CNC machining centers, professional process cells, wide-range welding equipment, automatic assembly lines and coating.

Ⅲ China's standard reference unit, to participate in the development of relevant valve industry standards.

Ⅳ We have set up a research and development center in Houston, Texas, in the United States.

Ⅴ Product Standard: GB, German Standard, American Standard, TUV CE, ISO 9001, ADWO-2000, TS, PED, WRC WRAS, KTW, API 6D, API609.

VI Main production: valvola a farfalla, valvola a sfera, valvola del cancello, valvola di ritegno, valvole globali, raccordi per tubi, attuatore manuale / pneumatico / elettrico, parti della valvola

FAQ

Q: If I need quotation, what informations do we need?

A: Valves' materials, Temperature, Pressure, Medium, Appllication System.

Q: Can you provide actuators, what you have?

A: Pneumatic, Electric, Hrdraulic, Solenoid Valves. RKSfluid actuators adopt USA technology. Which you need, just tell us.

Q: What's your productive capacity?

A: RKSfluid has four plants that can provide the products you need.

Q: Production lead time

A: Normal products have stock in 2~5 working days. Customized base on your need.

Q: MOQ

A: 1pc for all products.

Q: How about the quality assurance?

A: 100% quality test before delivery, 2 years warranty. Ensure your system working safety.

We got TUV, API, WRAS, CE, ISO certification.

Standard conform to DIN, ASME, BS EN, JIS, API, AWWA.

Q: How could you provide quality service to our customers?

A: RKSfluid own 20 years experiences and more than 70 R&D engineers provide technical support, model selection and installation guidance for you.

Etichetta:

valvola di riduzione della pressione

,Valvola di controllo idraulica

,Valvola del regolatore di pressione

,Valvola di controllo per acqua