- Browse Categories

- RKS BUTTERFLY VALVE

- Resilient Seat Butterfly Valve

- PTFE Lined Butterfly Valve

- High Performance Butterfly Valve

- Double Eccentric Butterfly Valve

- Triple Offset Butterfly Valve

- Sanitary Butterfly Valve

- RKS GATE VALVE

- RKS CHECK VALVE

- RKS Needle Valve

- RKS Control Valve

- RKS Air release valve

- RKS BALL VALVE

- RKS PIPE FITTING

- RKS GLOBE VALVE

- RKS ACTUATOR

- RKS FILTER

- Pig Launcher and Receiver

- RKS Fiberglass Pressure Vessels

- Main Product

- Contact Us

-

RKSfluid Flow Control Company

Web: www.rksfluid.com

Tel: +86 24 2318 0188

Fax: +86 24 2318 0788

Mail: info@rksfluid.com Contact Now

- Subscribe

-

Get email updates on new products

RKSfluid ductile iron lug type PTFE lined butterfly valve for seawater with handle lever

- Series: GRIFFIN series PTFE lined butterfly valve

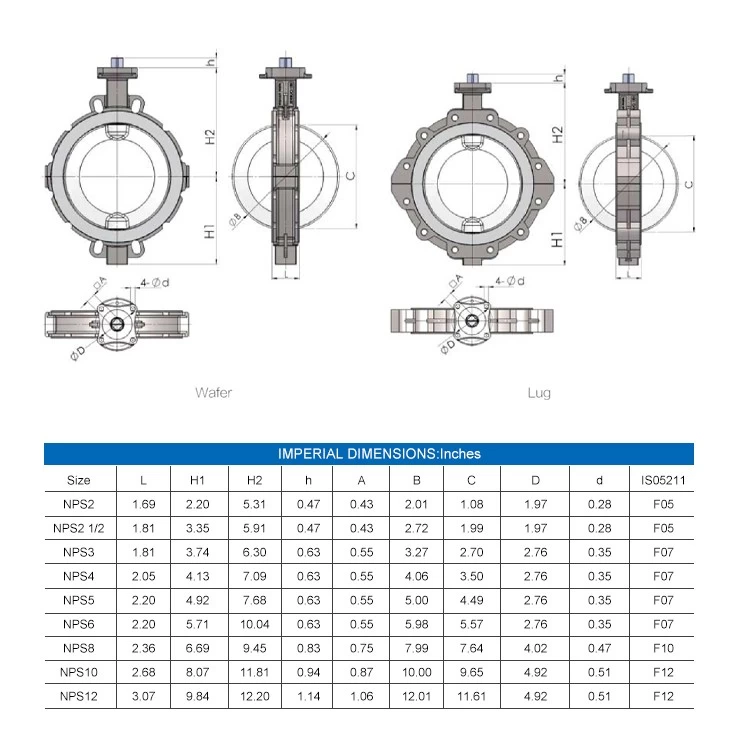

- Port size: DN50-DN300 (NPS2-NPS12)

- Pressure: PN6, PN10,PN16(150PSI)

- Body: WCB, CF8M, CF8

- Seat: PTFE

- Disc/Trim: Stainless steel/SS + PTFE/SS + PFA

- Stem: Duplex stainless steel (1.4462, 1.4469),Precipitation-hardening stainless steel (17-4PH),Stainless steel, CF8/CF8M/CF3/CF3M

- Connection: Wafer, Lug

- Standard: API,DIN,ASME,ISO,ANSI,GB/T,BS EN,AWWA

- Certificate: ISO9001: 2015, TUV, CE, WRAS, API, OHSAS

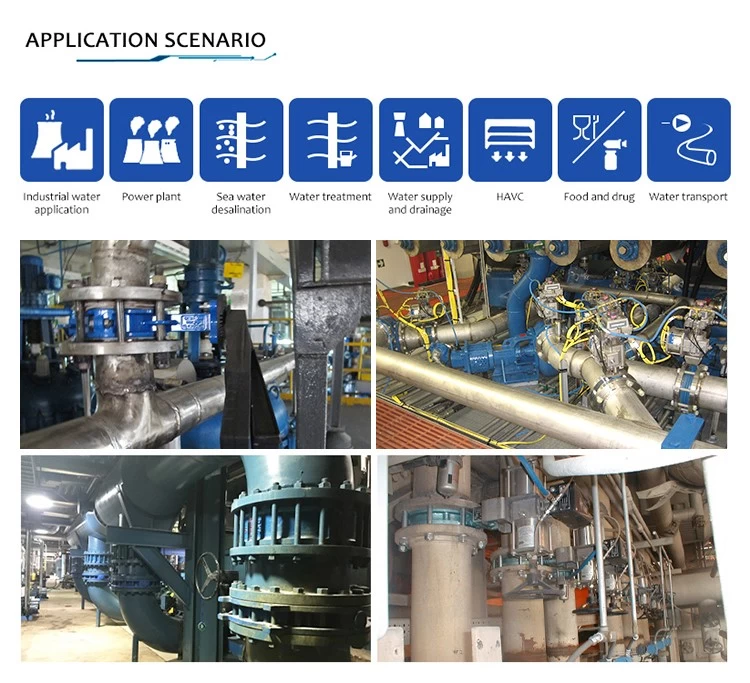

- Application: Acid-bases,Food,Medicine,Steel,Water,Plant Power,Oil

Description:

The two pieces of body wafer type butterfly valve and a concentric disc and seat configuration to with whole pack age PTFE sealed structure, takes whole package PTFE painting skills for the body. The painting thickness can reach up to 3~4mm, which effectively avoids the direct interaction between the body and the medium and the medium's corrosion for the body. Different painting skills and materials of valve's disc are taken according to the customer's need, such as PTFE and nylon painting, stainless steel and bronze material for the body, etc.

Feature:

1. Absolutely tight sealing with flow in either direction

2. The valve body and disc are accurately machined which results in low operating torque and long service life and reliability

3. PTFE liner seated prevents corrosion and guarantees long service life

4. Can be disassembled,material specific recycling possible

5. Can be installed at the end of pipe for lugged type butterfly valve

2. The valve body and disc are accurately machined which results in low operating torque and long service life and reliability

3. PTFE liner seated prevents corrosion and guarantees long service life

4. Can be disassembled,material specific recycling possible

5. Can be installed at the end of pipe for lugged type butterfly valve

Ⅰ Business area: fluid control products, technology and environmental protection products.

Ⅱ Advanced CNC machining centers, professional process cells, wide-range welding equipment, automatic assembly lines and coating.

Ⅲ China's standard reference unit, to participate in the development of relevant valve industry standards.

Ⅳ We have set up a research and development center in Houston, Texas, in the United States.

Ⅴ Product Standard: GB, German Standard, American Standard, TUV CE, ISO 9001, ADWO-2000, TS, PED, WRC WRAS, KTW, API 6D, API609.

VI Main production: butterfly valve, ball valve, gate valve, check valve, globe valves, pipe fittings, manual / pneumatic / electric actuator, valve parts.

Ⅲ China's standard reference unit, to participate in the development of relevant valve industry standards.

Ⅳ We have set up a research and development center in Houston, Texas, in the United States.

Ⅴ Product Standard: GB, German Standard, American Standard, TUV CE, ISO 9001, ADWO-2000, TS, PED, WRC WRAS, KTW, API 6D, API609.

VI Main production: butterfly valve, ball valve, gate valve, check valve, globe valves, pipe fittings, manual / pneumatic / electric actuator, valve parts.

FAQ

Q: If I need quotation, what informations do we need?

A: Valves' materials, Temperature, Pressure, Medium, Appllication System.

Q: Can you provide actuators, what you have?

A: Pneumatic, Electric, Hrdraulic, Solenoid Valves. RKSfluid actuators adopt USA technology. Which you need, just tell us.

Q: What's your productive capacity?

A: RKSfluid has four plants that can provide the products you need.

Q: Production lead time

A: Normal products have stock in 2~5 working days. Customized base on your need.

Q: MOQ

A: 1pc for all products.

Q: How about the quality assurance?

A: 100% quality test before delivery, 2 years warranty. Ensure your system working safety.

We got TUV, API, WRAS, CE, ISO certification.

Standard conform to DIN, ASME, BS EN, JIS, API, AWWA.

Q: How could you provide quality service to our customers?

A: RKSfluid own 20 years experiences and more than 70 R&D engineers provide technical support, model selection and installation guidance for you.

Q: If I need quotation, what informations do we need?

A: Valves' materials, Temperature, Pressure, Medium, Appllication System.

Q: Can you provide actuators, what you have?

A: Pneumatic, Electric, Hrdraulic, Solenoid Valves. RKSfluid actuators adopt USA technology. Which you need, just tell us.

Q: What's your productive capacity?

A: RKSfluid has four plants that can provide the products you need.

Q: Production lead time

A: Normal products have stock in 2~5 working days. Customized base on your need.

Q: MOQ

A: 1pc for all products.

Q: How about the quality assurance?

A: 100% quality test before delivery, 2 years warranty. Ensure your system working safety.

We got TUV, API, WRAS, CE, ISO certification.

Standard conform to DIN, ASME, BS EN, JIS, API, AWWA.

Q: How could you provide quality service to our customers?

A: RKSfluid own 20 years experiences and more than 70 R&D engineers provide technical support, model selection and installation guidance for you.

Tag:

resilient seat butterfly valve

,EPDM seat butterfly valve

,carbon steel body

,WCB body

,ductile iron body

,carbon steel WCB disc

,PTFE lined PFA coated Disc

,electric motor actuator

,API WRAS CE ISO etc

,Wafer connection type

,Lug connection type

,Flange connection type

,U-section short flange type

,water valve

,Oil, Water, Gas, Sewage