- Main Product

- Contact Us

-

RKSfluid Flow Control Company

Web: www.rksfluid.com

Tel: +86 24 2318 0188

Fax: +86 24 2318 0788

Mail: info@rksfluid.com Contact Now

- Subscribe

-

Get email updates on new products

News

Key Technical Approaches to Improving Candle Filter Performance

In industrial production, candle filters have become a core solution for solid–liquid separation due to their robust structure, high filtration accuracy, and stable performance. To achieve consistent and efficient filtration results, systematic optimization of operating conditions, filter media selection, and equipment management is essential.

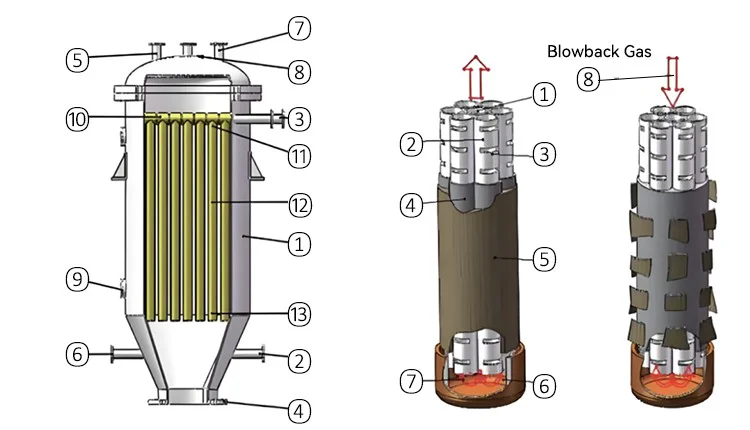

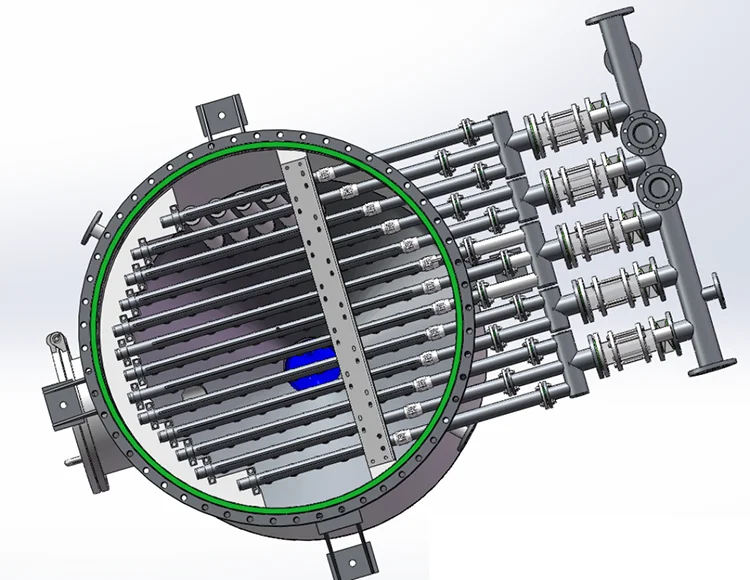

1. Understanding the Working Principle of Candle Filters

Candle filters operate through a combination of porous filter elements and filter media. During the filtration process, solid particles and impurities are retained on the surface of the filter cloth, forming a filter cake, while clarified liquid flows through the filter element and exits from the center.

The formation quality and thickness of the filter cake play a decisive role in filtration efficiency, flow stability, and overall system performance.

| 1. Filter Housing | 7. Instrumentation Port | 1. Central Tube / Filtrate Collection Tube |

| 2. Return Port | 8. Spare Port | 2. Perforated Support Tube / Filter Tube |

| 3. Filtrate Outlet | 9. Sight Glass | 3. Support Tube Openings / Perforations |

| 4. Discharge Port | 10. Filtrate Manifold | 4. Filter Media 5. Filter Cloth |

| 5. Overflow & Vent Port | 11. Filter Elements | 6. Collection Chamber (connecting filter tube to central tube) |

| 6. Feed Inlet | 12. Filter Media | 7. Filtrate exiting through the central tube |

2. Optimization of Filter Cake Formation

2.1 Selection of Appropriate Filter Cloth Materials

The material composition and pore size of the filter cloth directly affect filtration accuracy and filter cake structure. Based on slurry characteristics and particle size distribution, selecting a suitable filter cloth ensures uniform cake formation and stable adhesion to the filter surface, thereby improving filtration efficiency and product quality.

2.2 Control of Feed Pressure and Flow Rate

Feed pressure and flow rate are critical operating parameters. Excessive pressure may result in an overly dense or thick filter cake, increasing resistance and reducing throughput. Insufficient pressure, on the other hand, may lead to incomplete particle retention.

Optimizing feed pressure and flow rate according to process conditions helps achieve a balanced filter cake structure and stable filtration performance.

3. Filter Element Maintenance and Management

The filter element is the core component of a candle filter system, and its condition directly impacts filtration efficiency and operational reliability.

3.1 Regular Cleaning of Filter Elements

During operation, fine particles and process residues may accumulate on the filter surface, leading to increased pressure drop and reduced efficiency. Regular cleaning helps maintain a smooth filter surface and ensures consistent filtration performance.

3.2 Timely Replacement of Worn or Damaged Filter Elements

Filter elements that are damaged or excessively worn should be replaced promptly to prevent leakage, unstable filtration results, or system downtime.

4. Application of Intelligent Control Systems

With advances in automation technology, intelligent control systems are increasingly integrated into candle filter equipment. These systems enable real-time monitoring of key parameters such as feed pressure, flow rate, and filter cake thickness, and automatically adjust operating conditions based on process feedback.

The application of intelligent control not only improves filtration efficiency and process stability but also reduces manual intervention and operating costs.

5. Routine Inspection and Preventive Maintenance

In addition to filter element maintenance, regular inspection of the entire filtration system is essential. This includes checking mechanical components, sealing performance, and connection integrity. Early identification and resolution of potential issues help ensure stable operation, extended equipment lifespan, and reliable filtration performance.

If you require further information about candle filter products or filtration technologies, please feel free to contact us.

RKSfluid technical team is ready to provide professional consultation and customized filtration solutions.