- Main Product

- Contact Us

-

RKSfluid Flow Control Company

Web: www.rksfluid.com

Tel: +86 24 2318 0188

Fax: +86 24 2318 0788

Mail: info@rksfluid.com Contact Now

- Subscribe

-

Get email updates on new products

News

Candle Filter: A Breakthrough Solution for Purifying PVA Resin

Polyvinyl alcohol (PVA) resins are widely used in textiles, papermaking, pharmaceuticals, and specialty chemicals due to their excellent film-forming ability, adhesion, and biodegradability. However, during production, PVA solutions often retain catalyst residues, unreacted monomers, and colloidal particles. These “micron-level impurities” have a direct impact on product quality, especially for medical-grade and electronic-grade PVA.

Traditional filtration technologies struggle with high viscosity, high purity requirements, and extremely fine particles, making filtration the most challenging step in the entire production chain. The introduction of candle filters is now providing a breakthrough solution for these long-standing issues.

1. The Challenge: Removing Sub-Micron Impurities from PVA Resin

PVA production involves polymerization, alcoholysis, washing, drying, and multiple intermediate steps. Filtration and purification are crucial for determining the final product grade. For medical-grade PVA, the U.S. Pharmacopeia (USP) specifies:

- Particles >0.2 μm: fewer than 100 particles/mL

- Transmittance at 600 nm: ≥ 95%

- Metal ion content: <1 ppm

Yet traditional filtration systems face the following limitations:

- Extreme viscosity — PVA solutions may reach 3000–5000 cP, far beyond the handling capability of plate-and-frame filters

- Insufficient precision — Centrifuges cannot remove colloidal particles smaller than 5 μm

- High material loss — 5–8% product loss per batch, resulting in significant annual costs

Some manufacturers have even experienced export rejection due to 0.3 μm catalyst residues—highlighting how critical ultra-fine filtration has become.

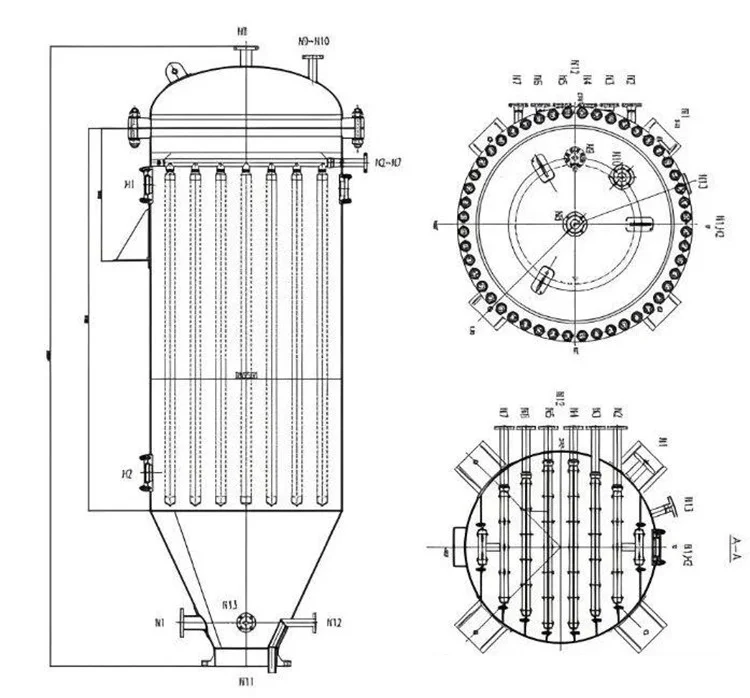

2. Candle Filter: A “Molecular-Level” Separation System

The strength of candle filters comes from the combination of gradient filtration and dynamic cake discharge (self-cleaning).

1. Gradient Filtration Structure (50 μm → 0.45 μm)

- Outer layer (50 μm): 316L sintered mesh for large particles and fibers

- Middle layer (≈5 μm): Multi-layer fiberglass composite to capture polymer gels

- Inner layer (0.45 μm): Nano-PTFE membrane for sub-micron precision

This layered structure enables stable, high-accuracy separation even with high-viscosity liquids.

2. Reverse Pulse Self-Cleaning

When the pressure drop reaches 0.5 MPa, the system triggers automatic pulse cleaning:

- 0.3-second release of 0.6 MPa nitrogen

- Cake removal efficiency above 98%

- Gas consumption below 0.1 m³/m²

This prevents filter blockage, extends service life, and ensures consistent filtration quality.

3. Four Key Advantages for PVA Filtration Lines

1) High Precision for Medical and Electronic Grades

- Filtration accuracy up to 0.45 μm

- Impurity removal ≥ 99.98%

- Light transmittance consistently above 90%

2) Lower Energy and Material Consumption

- 40% lower energy use due to optimized pressure-drop design

- Filter cake residue reduced to <0.3%

- A 50,000-ton/year PVA line can save over 8 million RMB annually

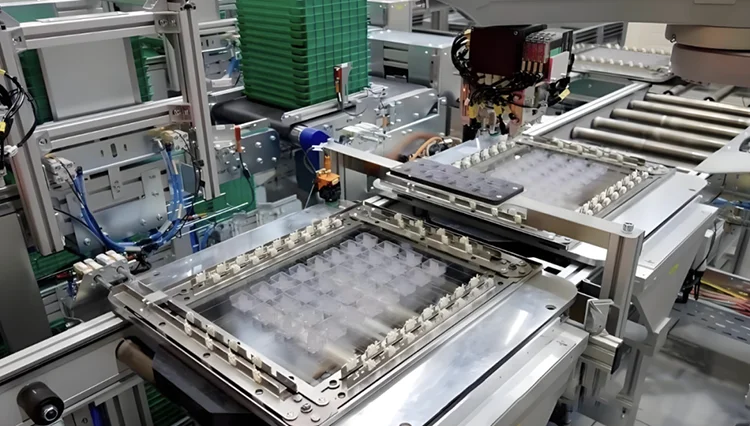

3) Intelligent Automated Control

- PLC monitors pressure, flow, and automatically manages cleaning cycles

- Reduced labor and lower operational uncertainty

4) Longer Service Life and Lower Maintenance Costs

- PTFE membrane with anti-corrosion surface treatment

- Each candle element withstands 5,000+ cleaning cycles

- Total maintenance cost reduced by up to 60%

4. Future Directions: Toward Smarter and More Flexible Filtration

As PVA applications expand into lithium-battery separators, LCD polarizer films, and medical film materials, filtration requirements are becoming even more demanding. New developments include:

- AI-based predictive maintenance to forecast filter element lifetime

- Modular filtration units enabling fast grade switching

- Green and sterile processes tailored for medical-grade production

Reach out to us for your customized candle filter solution.