- Browse Categories

- RKS BUTTERFLY VALVE

- RKS GATE VALVE

- RKS CHECK VALVE

- RKS Needle Valve

- RKS Control Valve

- RKS Air release valve

- RKS BALL VALVE

- RKS PIPE FITTING

- RKS GLOBE VALVE

- RKS ACTUATOR

- RKS FILTER

- Pig Launcher and Receiver

- RKS Fiberglass Pressure Vessels

- Main Product

- Contact Us

-

RKSfluid Flow Control Company

Web: www.rksfluid.com

Tel: +86 24 2318 0188

Fax: +86 24 2318 0788

Mail: info@rksfluid.com Contact Now

- Subscribe

-

Get email updates on new products

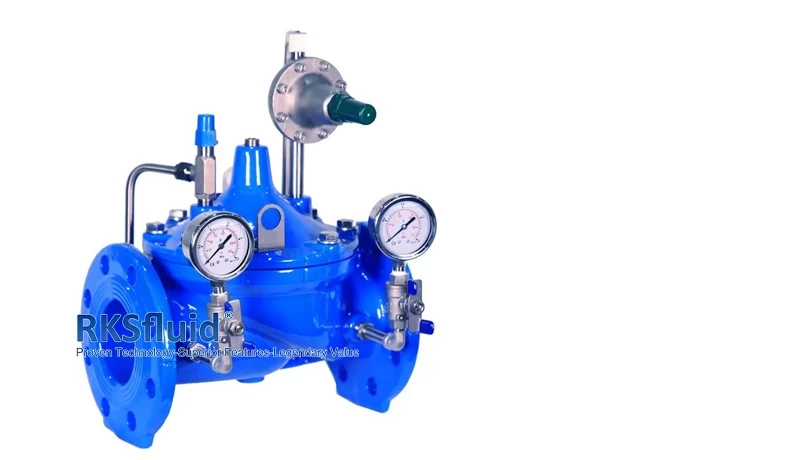

RKSfluid K2FB Pressure reduce valve with small flow by pass

- Customized Support: OEM. ODM

- Product Name: Pressure reduce valve with small flow by pass

- Application: Pipeline system need to provide a stable pressure to users

- Pressure Range: PN10/16/25/40GL150GL300

- Nominal Diameter: DN40-1200

- Material Option: QT500-7 /SUS304/SUS316/SAF2205/Bronze

- Seals Material: NBR/EPDM/HNBR

- Media: Water, Gas, Oil

- media temprature: -10~80℃

- Packing: Wooden Case

- Design Standards:CJ/T 219 & JB/T 10674 & EN 1074-5

- Pressure Level:PN10, PN16, PN25

- Stress Test Standard:GB/T 13927 & ISO 5208 &EN12266-1

- Flange drilling standard:GB17241.6; EN1092-2; ISO7005-2; ANSI / JIS / AS2129

- Structure Length:GB 12221 & EN558-1

- Face to Face:GB 12221 / EN 558-1 / ISO 5752 Series 1

Add the by pass pressure reduce pipe line with the main pressure reduce valve In the middle night or the ender user just need very small flow, the main valve is close, only the by pass pressure reduce pipeline is opening to control the stable outlet pressure

Application: Pipeline systems need to provide a stable pressure to users.

Application: Pipeline systems need to provide a stable pressure to users.

Standard Features

1. Single chamber and Globe type main valve;

2. Ductile Iron EN-GJS-500-7 body and bonnet;

3. CF8/SUS304 Seat and Shaft;

4. EPDM gasket and diaphragm;

5. WRAS Epoxy powder coating;

6. PN10/16/25

Main Valve -Fully Bore ( FB )

| DN | L | H2 | W | Port |

| 40 | 230 |

139 | 173 | 3/8'' |

| 50 | 230 | 139 | 173 | 3/8'' |

| 65 | 290 | 159 | 198 | 3/8'' |

| 80 | 310 | 179 | 226 | 3/8'' |

| 100 | 350 | 214 | 265 | 1/2'' |

| 125 | 400 | 278 | 307 | 1/2'' |

| 150 | 480 | 333 | 351 | 1/2'' |

| 200 | 600 | 600 | 436 | 3/4'' |

| 250 | 700 | 730 | 524 | 1'' |

| 300 | 850 | 850 | 606 | 1'' |

Hightlights:

1. Fully Bore with seat diameter as DN+2 mm

2. Stable working even if the flow close to Zero

3. High performance and strength Nylon enforce diaphragm

4. One Million cycle test and 64 bar burst test

5. Fully bore (FB), Reduce bore (RB) and Anti-Cavitation Device(ACD)

6. Higher than standard product test,

6. Higher than standard product test,

6.1 Seat test : 1.1 * PN + 1 Bar

6.2 Strength test : 1.5 * PN + 1 Bar

6.3 Low pressure sealing test: 0.2 Bar

7. Automatic computer test with 1000 Hz Sensor

8. Smart control valve and Solution system

9. Specialsolution for technical support

Ⅰ Business area: fluid control products, technology and environmental protection products.

Ⅱ Advanced CNC machining centers, professional process cells, wide-range welding equipment, automatic assembly lines and coating.

Ⅲ China's standard reference unit, to participate in the development of relevant valve industry standards.

Ⅳ We have set up a research and development center in Houston, Texas, in the United States.

Ⅴ Product Standard: GB, German Standard, American Standard, TUV CE, ISO 9001, ADWO-2000, TS, PED, WRC WRAS, KTW, API 6D, API609.

VI Main production: butterfly valve, ball valve, gate valve, check valve, globe valves, pipe fittings, manual / pneumatic / electric actuator, valve parts

Ⅱ Advanced CNC machining centers, professional process cells, wide-range welding equipment, automatic assembly lines and coating.

Ⅲ China's standard reference unit, to participate in the development of relevant valve industry standards.

Ⅳ We have set up a research and development center in Houston, Texas, in the United States.

Ⅴ Product Standard: GB, German Standard, American Standard, TUV CE, ISO 9001, ADWO-2000, TS, PED, WRC WRAS, KTW, API 6D, API609.

VI Main production: butterfly valve, ball valve, gate valve, check valve, globe valves, pipe fittings, manual / pneumatic / electric actuator, valve parts

FAQ

Q: If I need quotation, what informations do we need?

A: Valves' materials, Temperature, Pressure, Medium, Appllication System.

Q: Can you provide actuators, what you have?

A: Pneumatic, Electric, Hrdraulic, Solenoid Valves. RKSfluid actuators adopt USA technology. Which you need, just tell us.

Q: What's your productive capacity?

A: RKSfluid has four plants that can provide the products you need.

Q: Production lead time

A: Normal products have stock in 2~5 working days. Customized base on your need.

Q: MOQ

A: 1pc for all products.

Q: How about the quality assurance?

A: 100% quality test before delivery, 2 years warranty. Ensure your system working safety.

We got TUV, API, WRAS, CE, ISO certification.

Standard conform to DIN, ASME, BS EN, JIS, API, AWWA.

Q: How could you provide quality service to our customers?

A: RKSfluid own 20 years experiences and more than 70 R&D engineers provide technical support, model selection and installation guidance for you.

A: Valves' materials, Temperature, Pressure, Medium, Appllication System.

Q: Can you provide actuators, what you have?

A: Pneumatic, Electric, Hrdraulic, Solenoid Valves. RKSfluid actuators adopt USA technology. Which you need, just tell us.

Q: What's your productive capacity?

A: RKSfluid has four plants that can provide the products you need.

Q: Production lead time

A: Normal products have stock in 2~5 working days. Customized base on your need.

Q: MOQ

A: 1pc for all products.

Q: How about the quality assurance?

A: 100% quality test before delivery, 2 years warranty. Ensure your system working safety.

We got TUV, API, WRAS, CE, ISO certification.

Standard conform to DIN, ASME, BS EN, JIS, API, AWWA.

Q: How could you provide quality service to our customers?

A: RKSfluid own 20 years experiences and more than 70 R&D engineers provide technical support, model selection and installation guidance for you.

Tag:

WCB body

,ductile iron body

,API WRAS CE ISO etc

,Flange connection type

,pressure reducing valve

,hydraulic control valve

,pressure regulator valve

,control valve for water

,EPDM seat

,water valve

,Oil, Water, Gas, Sewage