- Main Product

- Contact Us

-

RKSfluid Flow Control Company

Web: www.rksfluid.com

Tel: +86 24 2318 0188

Fax: +86 24 2318 0788

Mail: info@rksfluid.com Contact Now

- Subscribe

-

Get email updates on new products

News

RKSfluid® Basket Strainers – Reliable Solid-Liquid Separation Solutions

RKSfluid® specializes in the production of candle filters, basket strainers, Cartridge filter, and other advanced filtration systems. We are committed to providing comprehensive and customized solid-liquid separation solutions tailored to diverse industrial applications.

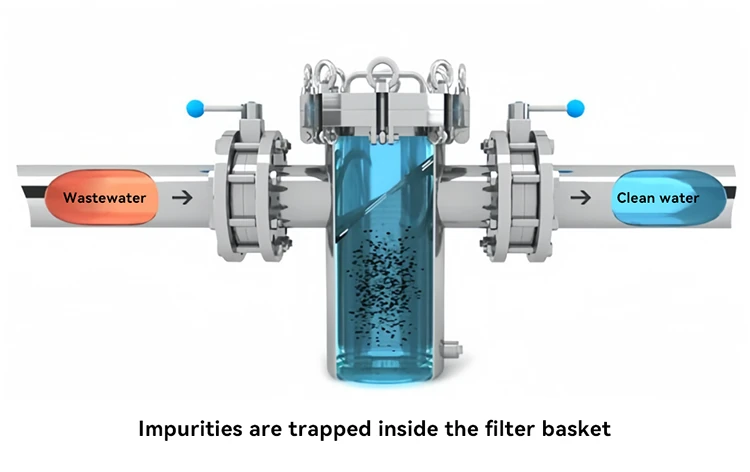

Working Principle of Basket Strainers

The basket strainer operates mainly on the principles of particle sedimentation and mechanical interception by the filter medium. Its working process can be summarized as follows:

1. Filtration Process

Fluid Inlet:

When the unfiltered liquid enters the basket strainer through the inlet, it flows into the internal chamber of the equipment.

Impurity Interception:

As the liquid passes through the filter basket, larger solid particles and impurities are trapped on the inner surface of the mesh. Over time, these particles accumulate to form a filter cake. The basket mesh, usually made of porous materials, is precisely engineered with openings smaller than the particle size to be intercepted, ensuring high-efficiency filtration.

Clean Fluid Outlet:

The purified liquid passes through the filter mesh and flows to the outlet, achieving effective solid-liquid separation and delivering clean, stable fluid.

2. Maintenance & Operation

Cleaning or Replacing the Filter Basket:

During operation, impurities gradually build up on the filter basket, increasing flow resistance and causing a higher pressure drop. When the pressure drop reaches a critical level, it indicates the need for cleaning or replacement. The process involves shutting off the inlet and outlet valves, releasing internal pressure, opening the flange cover, and removing the filter basket for cleaning. After cleaning, the basket is reinstalled, and the system resumes operation.

Simple Structure, Easy Maintenance:

Basket strainers feature a straightforward design that requires no additional energy input—filtration is achieved solely by fluid pressure. Routine maintenance is convenient, as operators simply remove, clean, and reinstall the basket at regular intervals.

RKSfluid Advantages

RKSfluid basket strainers are equipped with precision-engineered filter baskets and premium-quality meshes, enabling efficient capture and removal of impurities and solid particles from fluids. This ensures the purity, stability, and reliability of the output fluid, safeguarding the quality of your products.

Whether in petrochemical, titanium dioxide, lithium battery, chemical processing, biopharmaceutical, or water treatment industries, RKSfluid delivers tailored filtration solutions to meet your specific needs.