- Main Product

- Contact Us

-

RKSfluid Flow Control Company

Web: www.rksfluid.com

Tel: +86 24 2318 0188

Fax: +86 24 2318 0788

Mail: info@rksfluid.com Contact Now

- Subscribe

-

Get email updates on new products

News

RKSfluid Desalination Project-2019

This project is the desalination project of the island of Vietnam by RKSfluid. We design, procurement, installation, debugging and acceptance of the desalination system are qualified. After the acceptance is passed, the owner can be given unified guidance training. The scale of construction is 15m3/h.

1.1 Company Profile

RKSfluid Flow Control Company is part of the RKSfluid Group. located in Liaoning province,China., registered capital of RMB 100 million. It is a professional environmental protection system integrating R&D, design, manufacturing, installation and commissioning, training consultation and environmental protection design, installation, operation and maintenance of environmental protection equipment. enterprise.

The company's business scope covers environmental protection equipment manufacturing, sewage treatment engineering, atmospheric treatment engineering, and water treatment engineering. It can provide customers with pre-feasibility demonstration and technical consultation for the project; design, construction, installation and commissioning during the project implementation period; Operation management and after-sales service and technical support.

The series of sewage treatment equipment has the advantages of stable performance, good treatment effect, low investment, small land occupation and convenient maintenance, and has reached the domestic leading level.

The company's products have been successfully operated in various parts of the country. The fields involve municipal sewage, sewage from medical institutions, domestic sewage, rural environmental management, various industrial sewage, circulating cooling water, sewage treatment plants, and reuse of water. All provinces and cities in China have been praised and affirmed by the majority of users.

Our company's various products are guided by the "preferential price, excellent quality, and high-quality service". Based on the service tenet of "improving water quality, benefiting humanity, quality first, customer first", we constantly climb the peak of technology and promote Leading the era of high-tech technology and the development of environmentally friendly energy-saving products.

The development of an enterprise is inseparable from independent innovation. In the process of development, RKSfluid has formed the enterprise characteristics of “technology first, action ahead”, continuously increasing capital investment in the field of technological innovation, and implementing the requirements of sustainable development strategy. With the latest independent innovation technology to integrate the world's latest scientific and technological achievements, the company's development has always been at the forefront of technological innovation.

1.2 Design scope

1) Technical plan for seawater engineering.

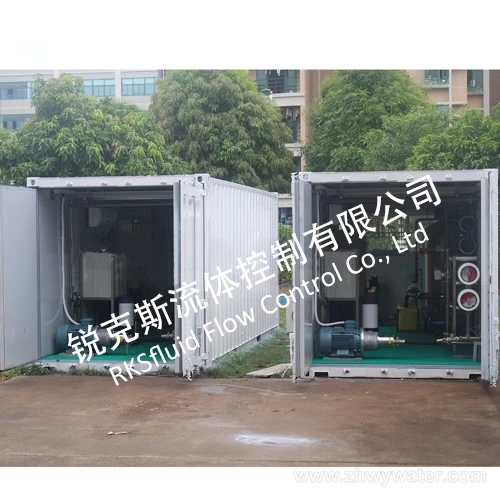

2) Design and manufacture of mobile container desalination equipment.

1.3 Engineering Features

1) Saving land, all process equipment can be integrated in the container to meet the needs of seawater desalination system;

2) The construction period is short, all equipment can be integrated and installed in China, and only the pipeline connection is needed after the situation, which can shorten the construction period and reduce the labor cost;

3) The operation is stable, the seawater desalination process is advanced and mature, and the production can be stabilized, and the owner's worries can be relieved.

1.4 Description of seawater desalination process selection.

For the seawater desalination treatment project of this project, the whole seawater desalination system needs to be installed in the container container. Therefore, the selected seawater desalination process must significantly reduce the footprint when the effluent quality is met. Moreover, the materials selected for the process equipment must be resistant to salinity.

1. The seawater flows into the seawater collection tank. The seawater lifting pump is installed in the pool. The pump shaft and impeller are made of 2205 material, which is resistant to seawater corrosion.

2. The lifting pump raises the seawater to the active sand filter tank. The active sand filter tank can roughly filter out the impurities in the seawater and protect the subsequent processing equipment. The filter tank body is made of FRP.

3. The effluent from the activated sand filter tank flows into the activated carbon filter tank, and the activated carbon filter system can further remove impurities in the seawater.

4, activated carbon filter tank effluent into the security filter, and add scale inhibitor. The security filter guarantees the seawater quality of the influent reverse osmosis system, and the addition of scale inhibitors can reduce the membrane cleaning frequency.

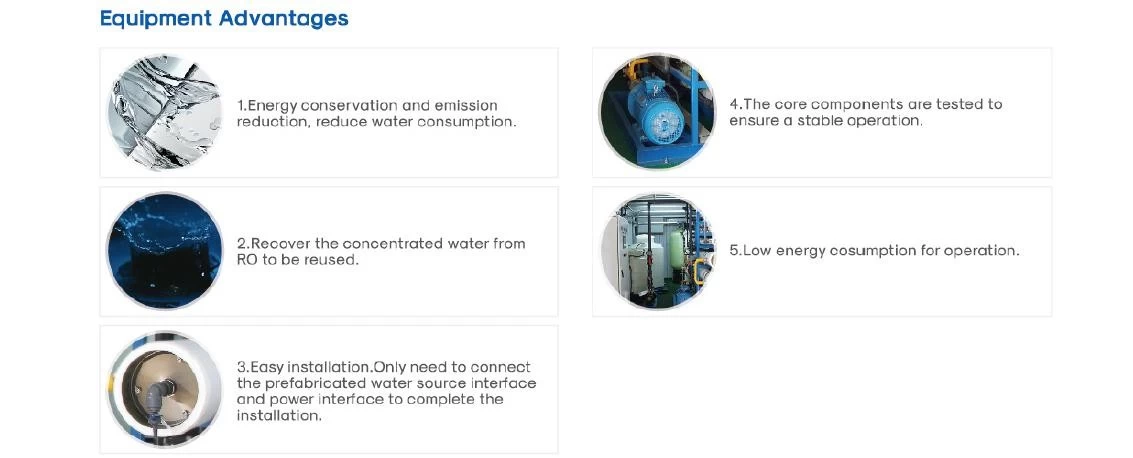

5. The security filter effluent enters the reverse osmosis system. Reverse osmosis, also known as reverse osmosis, is a membrane separation operation that uses a pressure difference as a driving force to separate a solvent from a solution. Pressure is applied to the liquid on one side of the membrane. When the pressure exceeds its osmotic pressure, the solvent reversely penetrates against the direction of natural permeation. Thus, a permeated solvent, that is, a permeate, is obtained on the low pressure side of the membrane; and a concentrated solution, that is, a concentrate, is obtained on the high pressure side. The seawater is treated by reverse osmosis, fresh water is obtained on the low pressure side of the membrane, and brine is obtained on the high pressure side. The reverse osmosis system is the core process for seawater desalination. The reverse osmosis system is equipped with a chemical cleaning device to clean the membrane system according to the actual situation of the field data. The reverse osmosis produces concentrated water to pressurize the front end seawater by the action of the energy recovery device.

6. After the reverse osmosis treatment, the seawater enters the production tank through the UV disinfection device, and the water supply pump can supply water to each water point.