- Main Product

- Contact Us

-

RKSfluid Flow Control Company

Web: www.rksfluid.com

Tel: +86 24 2318 0188

Fax: +86 24 2318 0788

Mail: info@rksfluid.com Contact Now

- Subscribe

-

Get email updates on new products

News

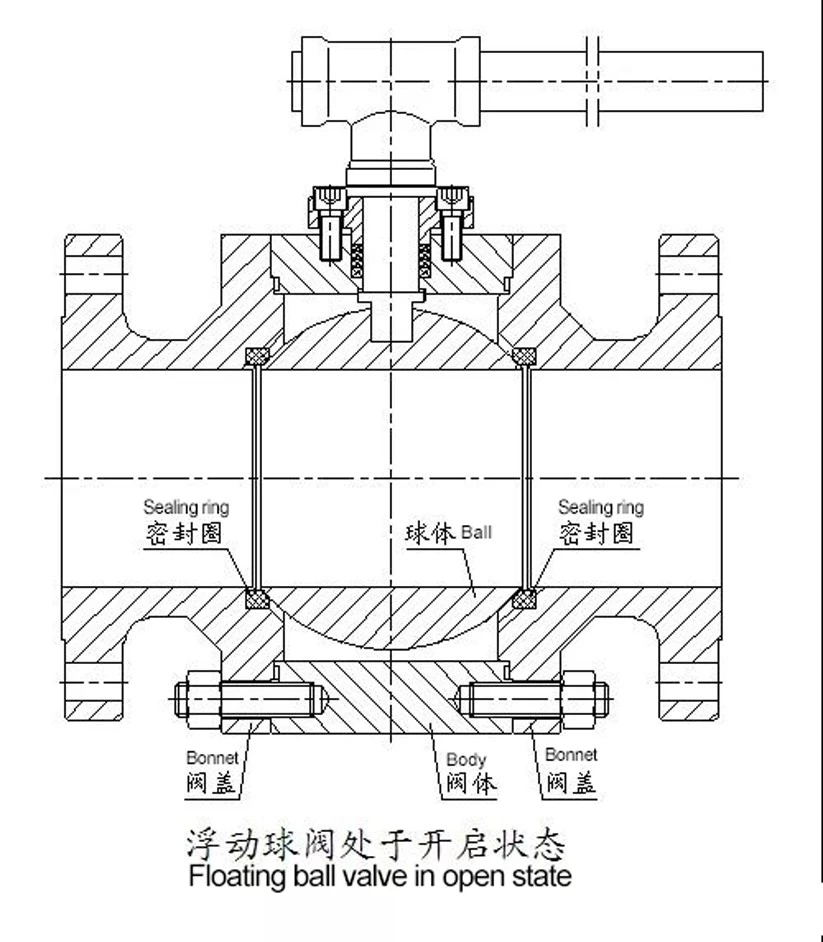

The working principle of floating ball valve

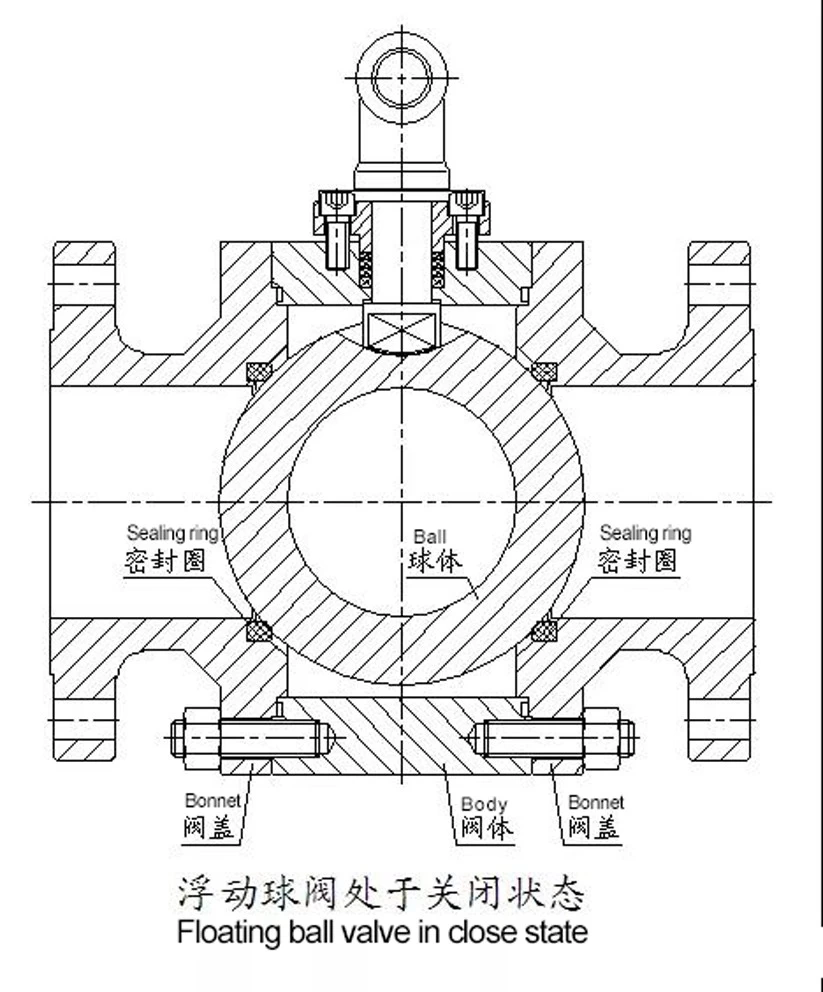

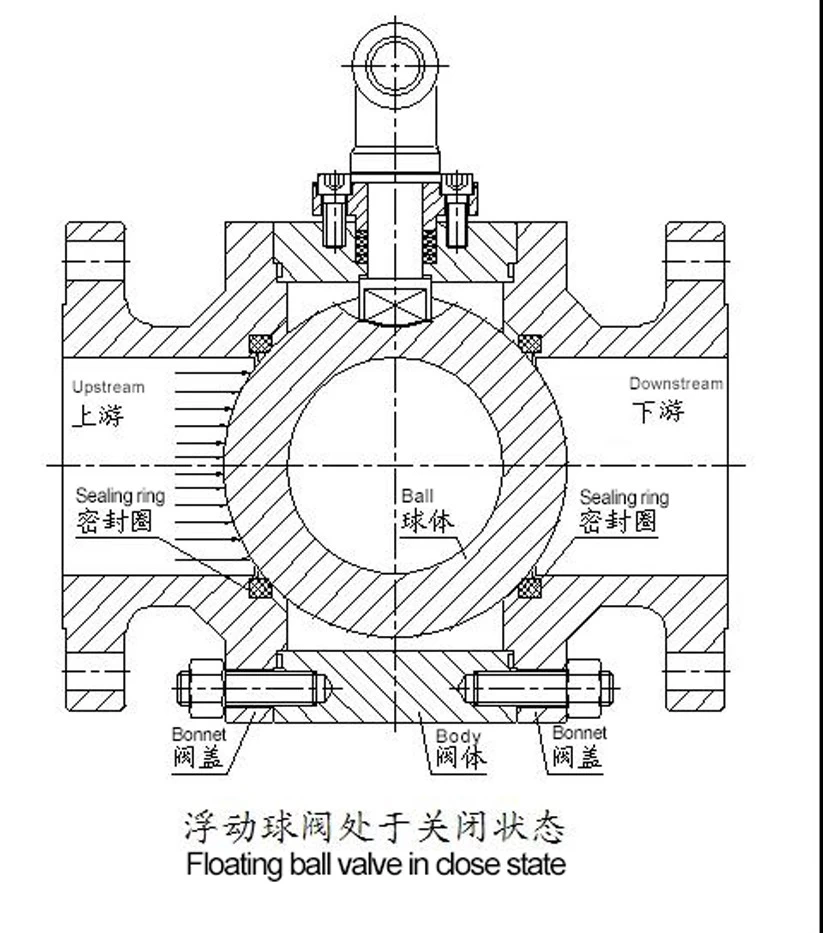

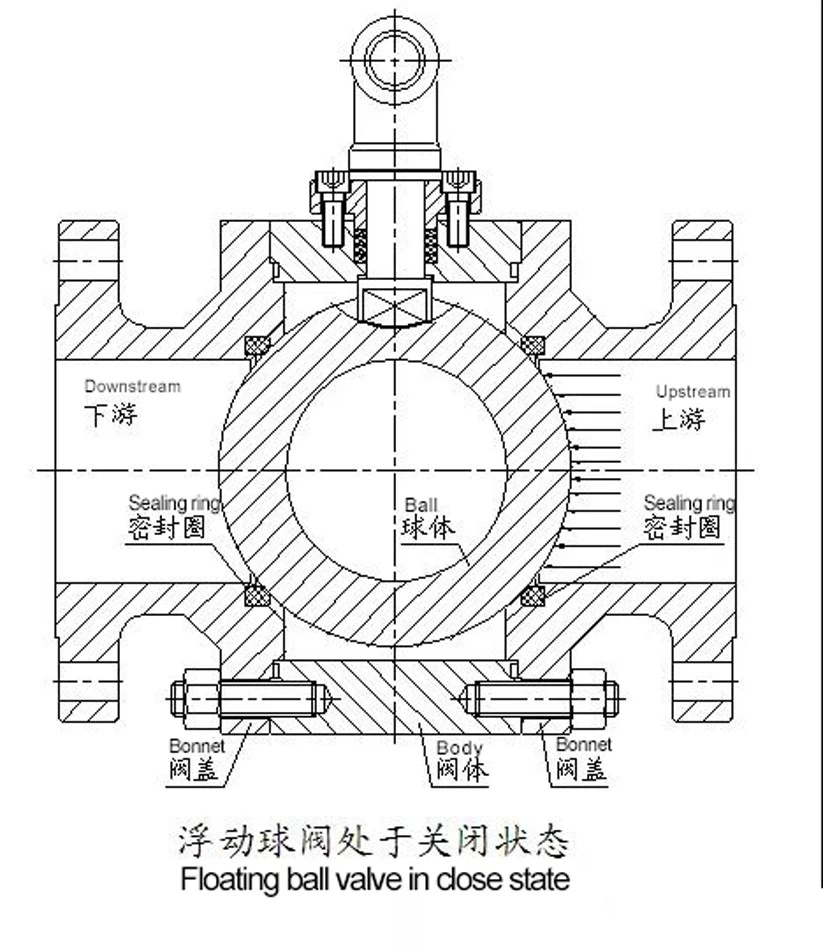

The sealing principle of the floating ball valve, because the ball of the floating ball valve is not restricted by any component, when the valve is in the closed state, the medium is pressed from one end (upstream) of the valve, the ball can generate a certain displacement and press at the outlet end of the valve ( On the sealing surface of the downstream), an outlet end seal is produced.

Advantages of the floating ball valve: the valve has small flow resistance, simple structure, good sealing performance, and high cost performance in a certain caliber and a certain pressure range.

Disadvantages of the floating ball valve: the load of the working medium of the ball will all act on the downstream sealing ring. At the same time, the gravity of the ball itself will be directly absorbed by the sealing ring. Therefore, if the valve pressure is too high, or the caliber is too large, it will Causes the following problems:

1. As shown in Figure 2, the load on the working medium of the sphere (F1) = ball valve runner area (S) * valve nominal pressure (PN / MPA)

It can be seen from the above formula that (1), when the valve diameter is constant, the larger the nominal pressure of the valve, the greater the load on the working medium of the sphere; when the nominal pressure of the valve is constant, the larger the valve diameter, the sphere The greater the load on the working medium.

Therefore, the valve of the same diameter, when the nominal pressure is large enough, it is not suitable for the floating ball valve structure; the valve of the same nominal pressure, when the diameter is large to a certain extent, is not suitable for the floating ball valve structure.

2. Because the gravity of the ball itself will be directly received by the seal ring, when the ball weight is too large, the different positions of the seal ring will be severely uneven, resulting in irregular deformation of the seal ring, affecting the valve life or valve seal. Therefore, when the caliber is large enough, no matter how low the pressure is, it is not suitable for the floating ball valve structure.

3. The torque of the ball valve is mainly from the friction between the ball and the seal.

There is a concept in the mechanical foundation: the friction between two objects (M) = positive pressure (F) * friction coefficient (f)

The coefficient of friction (f) is determined by the nature of the material itself, the material is selected, and the coefficient of friction is constant.

The positive pressure (F) is proportional to the load (F1) of the working medium that the ball is subjected to.

Therefore, when the load (F1) of the working medium of the ball is large, the friction between the ball and the sealing ring will be large, and the torque of the floating ball valve will also increase. Therefore, when the valve diameter is constant, the larger the nominal pressure of the valve, or the larger the valve nominal pressure, the larger the valve diameter will greatly increase the torque of the ball valve.

In general, the selection specifications of the floating ball valve can be referred to as follows:

PN ≤ 2.5MPA (or 150lb), DN ≤ 200mm (or 8")

(DN≤200mm (or 8") is a defective product, preferably a fixed ball valve)

PN=4.0MPA (or 300lb), DN≤150mm (or 6”)

DN ≤ 150mm (or 6") is a defective product, preferably a fixed ball valve)

PN=10.0MPA (or 600lb), DN≤100mm (or 4”)

PN=16.0MPA (or 900lb), DN≤50mm (or 2”)

PN=25.0MPA (or 1500lb), DN≤40mm (or 1.5”)

PN=42.0MPA (or 2500lb), DN≤25mm (or 1”)

If the actual manufacturer exceeds the above specification range and adopts the floating ball valve structure, due to the structural characteristics of the floating ball valve, the valve will also have a high fixed torque ball valve with the same torque. At the same time, the service life will be shortened. Please be cautious use.